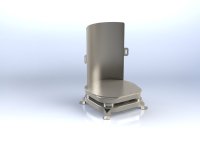

Bin Shaker

The Bin Shaker that has been developed by CDM is suited to viscous products (dry or wet) that require non aggressive movement to either mix or agitate in a gentle to semi aggressive centrifugal throw motion.

This process is sometimes preferred to more vigorous processes that may damage vulnerable, delicate or easily foamed products.

The mixing motion can be varied in throw from 5mm to 10mm as well as speed regulation up to 100rpm, thus allowing the ultimate mixing motion for differing products.

Mixing in this fashion achieves a gentle circular mixing motion of the ingredients within the drum.

Unlike any other mixer on the market today, this mixer is unparalleled in performance for delicate and troublesome products.

- Base frame and drive: The base of the shaker frame contains the integrated gear drive (integral within foot print) and four feet that require fastened to the ground/substrate. This is the base structure that takes the reactive load from the moving mass above so needs to be secure.

- Eccentric Drive and Idlers: These are the heart of the design that rotate and oscillate the above componentry as they rotate.

- Top table and drum carrier: Connected to the oscillating drive and idlers is the drum carriage doing the work of oscillating the table with the drum strapped in.

- Flexible: Flexibility has been included with use of an electronic drive which allows for speed variation with ramp up and ramp down functionality as well.

- Mechanical flexibility has also been allowed for with manually changeable offset of the oscillation which can be changed from 5mm (small throw), 8mm (medium throw), or 10mm offsets (aggressive throw) (10mm, 16mm, 20mm total throw).

- Having both of these variables gives a high degree of control that can be changed and tweaked to get the most efficient/required mixing action for your product.

| Capacity | 200L/55-US-Gal drum up to 200kg weight |

|---|---|

| Drive | .37kw SEW W30 integral motor/gearbox |

| Secondary Drive | Triple vee belt |

| Throw | 5 – 8 – 10mm |

| RPM | 0 – 100 rpm |