Design Services

How the design process typically works

Design can be driven by numerous factors including company health and safety, product handling difficulties, staff availability, new product controls, legislation and the list goes on.

CDM can advise from experience in a wide array of industries for best practice solutions but are also happy to listen to new innovative ideas that we can then design to your requirements. We are all about innovation and are constantly working on new ideas to find solutions & solve problem areas.

Our first consultation is usually a brief on your business to get to know the ins and outs of your operation, product expectations, risk factors, volumes, available real estate, etc.

Brainstorming will then take place to develop solutions to the problem, product or new development (in conjunction with the client as required). This is where we gather ideas that help with design intent to make the modelling process more streamlined.

Risk assessments and viability studies etc. may take place at this point, or sometimes after modelling a concept to give a clearer picture.

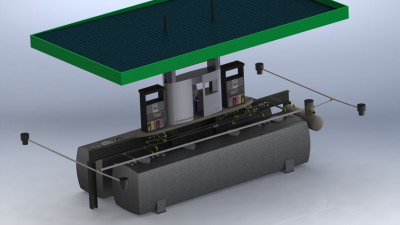

3D modelling of concepts/designs are then generated for client approval or discussion (larger projects staged to areas, smaller projects not so much).

With client approval of concept detail, modelling of critical manufactured items are then completed and drawings produced for manufacturing. Layouts, process flows, and other drawings may also be required dependent upon project.

We at CDM design with materials actually available at the time of design and try to stay with the most common materials where possible, which usually aids in minimising build costs and time lines.

Contact us here if you have ideas you would like to realise and let us help you make them come true.